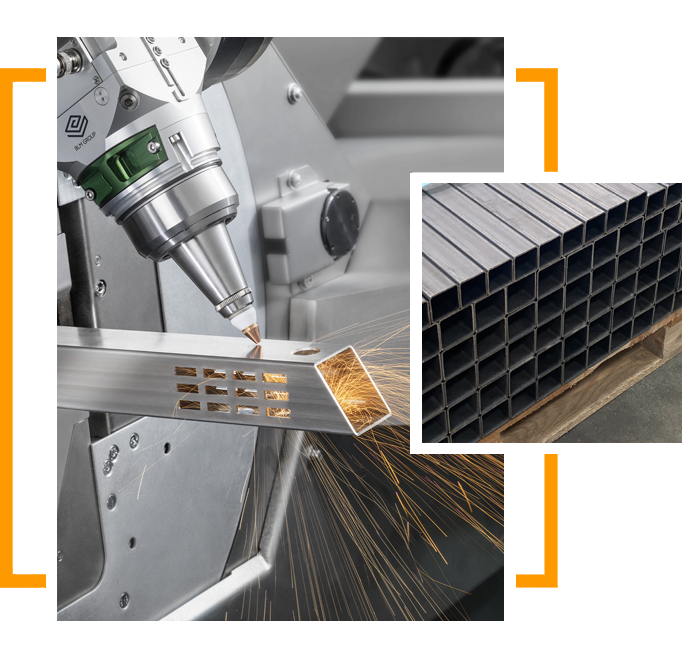

Thanks to our investments in laser tube cutting technology, WEC Laser is also able to laser cut box section and most open profiles such as angle and channel, cutting up to a maximum envelope size of 200mm x 200mm, 6.5m long and 12mm thick.

Laser Box Section Cutting

Our Capabilities

Mild Steel Laser Cut Box Sections

Mild steel box section are traditionally used for making structures and general fabrications. It can be easily cut and drilled on our tube laser cutters and is particularly suited to welding and general fabrication. Our box laser cutting service enables us to cut and drill mild steel box section with a maximum wall thickness of 12mm.

Stainless Steel Laser Cut Box Sections

Stainless steel square and rectangular box section are used for general fabrication. Our box laser cutting service enables us to cut and drill stainless steel box section with a maximum wall thickness of 10mm.

Aluminium Laser Cut Box Sections

Thanks to recent investments, we can also laser cut square and rectangular alumnimium box section with a maximum wall thickness of 5mm. Aluminium box sections are generally used for making frames and general fabrications.

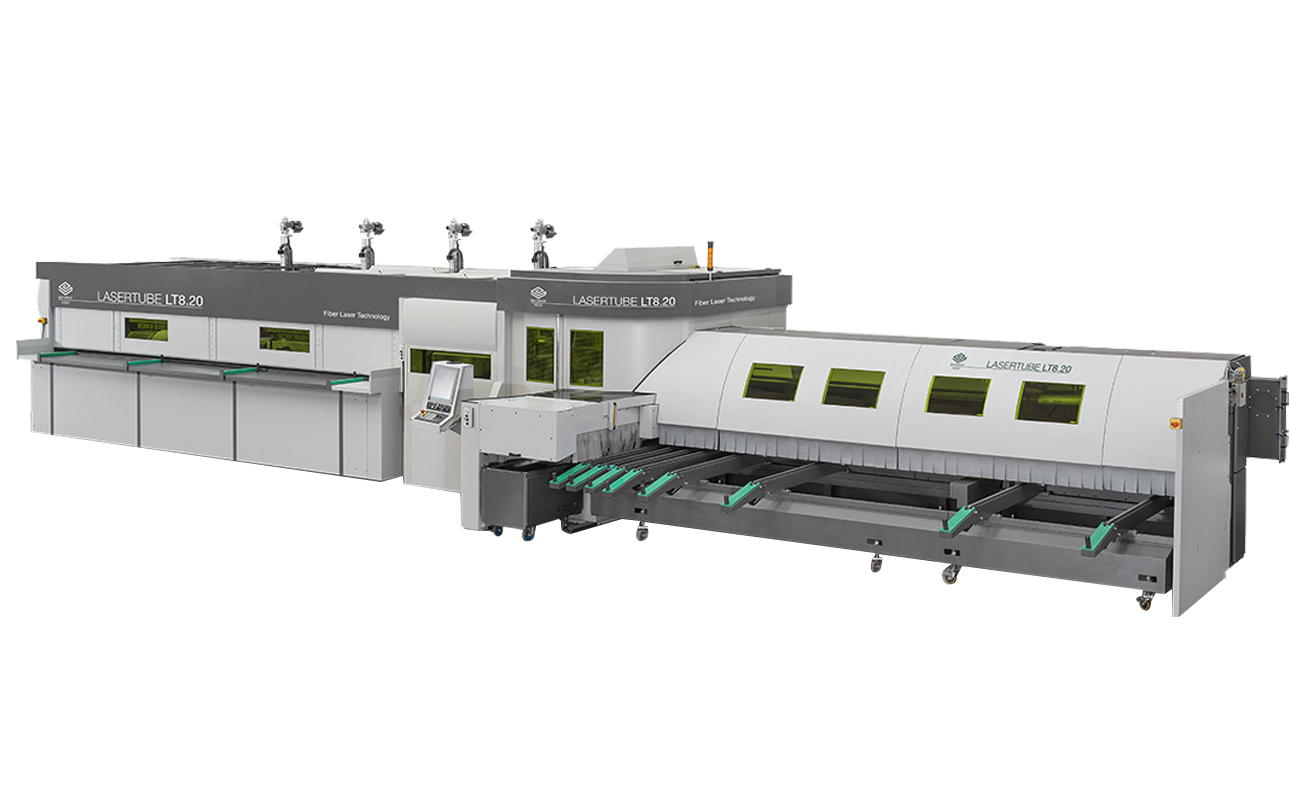

Our Laser Box Section Cutting Capacity:

| Machines | Capacity | Thickness |

|---|---|---|

2 Fully Automated Tube fiber Lasers both 8.5m feed with 6.5m unload. Tubes: Round, square, rectangle, flat sided oval Open profiles: Angle, flat, channel (not H or I) Special profiles: Feasable but subject to verification | Tube: Up to Ø 240mm Box: up to Ø 200 x 200mm RSA: up to 200 x 200mm Max. Weight: 225kg Max weight per single tube: 40kgs/m Max. component length: 6.5m Max. bundle loading weight: 5000kgs Fully automatic bar handling from bundle including: measuring, feeding, cutting & unloading. | 12mm Mild steel 10mm Stainless steel 6mm Aluminium 4mm Copper 6mm Brass |

Why Choose WEC Laser?

WEC Laser, part of WEC Group, has established itself as one of the UK's largest laser cutting companies, with a workforce of more than 900 dedicated professionals in laser cutting, tube cutting, fabrication, powder coating, CNC machining, plasma cutting, and waterjet cutting divisions. WEC Laser provides a comprehensive one-stop-shop service to all of its clients and we can cater for any manufacturing needs, from small one off brackets to ongoing £multi-million contract manufacturing projects. We offer competitive prices with diverse machines ensuring cost-effective laser cutting solutions. Our team provides fast quotes within 24 hours and next-day cutting for urgent needs via our SILVER service. Operating 24/7, we maximise productivity and reduce costs, with efficient nationwide delivery from our central UK location. We cater to all needs from prototypes to large batches, maintain high quality with ISO 9001:2015 certification, support intricate designs with our CAD/CAM office, and stock common grades of steel and aluminium to meet your requirements promptly. Learn more about why WEC Laser is your ideal manufacturing solution.

Frequently Asked Questions

Laser box cutting is a precision manufacturing process that utilises laser technology to cut materials, typically metals (stainless steel, mild steel, aluminium, brass, & copper), into specific shapes and dimensions for box construction. This technique employs a high-powered laser beam directed through a computer-controlled system to achieve highly accurate and intricate cuts with smooth edges, minimising material waste. Laser box cutting is commonly used in industries such as packaging, electronics, and automotive for creating custom-fit boxes, enclosures, and components with complex geometries that traditional cutting methods might struggle to achieve efficiently.

Steel box sections, also known as hollow structural sections (HSS), come in various shapes and sizes. The main types of steel box sections include:

Square Hollow Sections (SHS):

These sections have equal dimensions on all four sides, creating a square cross-section. Commonly used in columns, beams, and other load-bearing applications.

Rectangular Hollow Sections (RHS):

These sections have unequal dimensions, creating a rectangular cross-section.

Used in applications where a flat surface is needed for connection or aesthetic purposes.

Circular Hollow Sections (CHS):

These sections have a circular cross-section. Often used in structural applications requiring torsional rigidity and aesthetic appeal.

Elliptical Hollow Sections (EHS):

These sections have an elliptical cross-section.

Used in architectural applications where aesthetics are important.

Construction: Columns, beams, trusses, and framework in buildings and bridges.

Manufacturing: Machinery frames, support structures, and equipment.

Transportation: Frames for vehicles, trailers, and railway cars.

Architecture: Decorative elements, railings, and structural supports.

Material and Specification

Materials: Typically made from hot-rolled or cold-formed steel.

Specifications: Governed by various standards such as ASTM, EN, and ISO, which dictate dimensions, tolerances, and mechanical properties.

Ease of Fabrication: Can be easily cut, welded, and shaped to fit specific design requirements.

21

Flat Bed Lasers

24

Press Brakes

4

Tube Lasers

24h

Cutting Capacity

Our Additional Services

Laser Box Section Cutting

Contract Manufacturing Services

Waterjet Cutting

Sheet Metalwork and Fabrication

Metal Bending and Folding

Angle, Channel & Open Profile Cutting

Laser Tube Cutting

What our Customers have to say about WEC Laser...

"Met with Stephen today who showed me around the facilities and helped me with an ongoing project. The machinery and level of organisation is honestly breathtaking, having seen much of the work in progress I am very much looking forward to working with WEC."

"Just called to enquire about a replacement part for a post. Don't know much about them but John quickly pointed out what I needed and said he'd get one sent out in the post. Too easy. Thanks."

"Reliability and competitive prices plus helpful staff is why we work with WEC Laser"

“Delivery standards are always excellent. They are always on time."

Check out our latest video

WEC Laser is one of the UK's leading laser cutting company offering flat-bed, tube and box section laser cutting services throughout the UK. With 21 lasers we are one of Europe's largest laser cutting operations