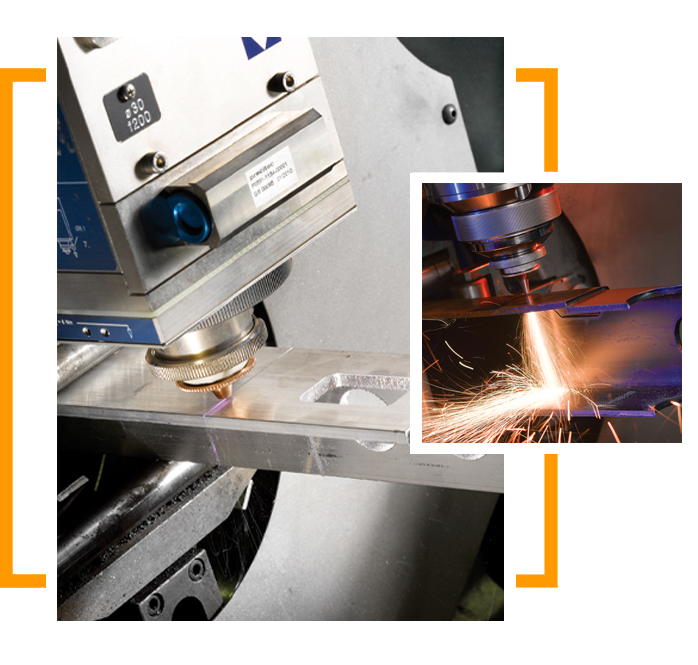

Thanks to our investments in the latest tube cutting technology, WEC Laser also offer a quality laser cutting service for angle, channel and open profile parts of up to 6.5m long and 200mm x 200mm in size.

Angle, Channel & Open Profile Cutting

Our Capabilities

Our laser cut angle, channel and open profile capabilities enables us to offer massive cost and time savings to our customers on parts that would have normally required several complex operations. Our angle and channel laser cutting capability enables us to manufacture complete parts in one hit, which can be over 90% faster than other conventional cutting processes such as sawing, milling, drilling and punching.

We are able to cut angles and channels to size, whether they are stainless steel, mild steel, or aluminium. Our highly skilled team operate 24/7, meaning all of your angle and channel laser cutting requirements are completed as quickly as possible.

With a minimum capacity of 30mm x 20mm and maximum 200mm x 200mm, we have the facilities to cater for your needs. To compliment our angle and channel laser cutting, we also provide a number of other services including CNC Machining, small to large fabrication, Sheet Metalwork, Large Fabrication, coded welding and powder coating, all under one roof.

Our Angle, Channel and Open Profile Cutting Capacity:

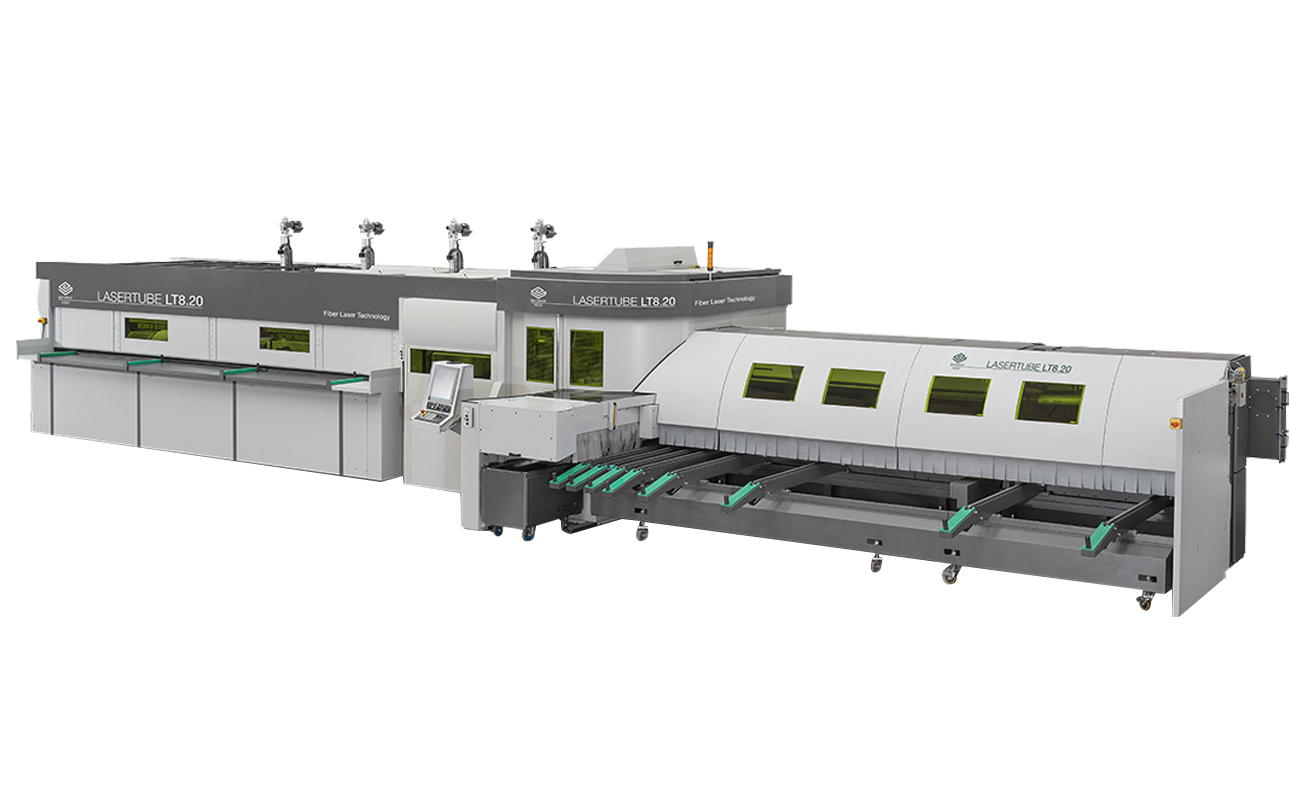

| Machines | Capacity | Thickness |

|---|---|---|

2 Fully Automated Tube fiber Lasers both 8.5m feed with 6.5m unload. Tubes: Round, square, rectangle, flat sided oval Open profiles: Angle, flat, channel (not H or I) Special profiles: Feasable but subject to verification | Tube: Up to Ø 240mm Box: up to Ø 200 x 200mm RSA: up to 200 x 200mm Max. Weight: 225kg Max weight per single tube: 40kgs/m Max. component length: 6.5m Max. bundle loading weight: 5000kgs Fully automatic bar handling from bundle including: measuring, feeding, cutting & unloading. | 12mm Mild steel 10mm Stainless steel 6mm Aluminium 4mm Copper 6mm Brass |

Why Choose WEC Laser?

WEC Laser, part of WEC Group, has established itself as one of the UK's largest laser cutting companies, with a workforce of more than 900 dedicated professionals in laser cutting, tube cutting, fabrication, powder coating, CNC machining, plasma cutting, and waterjet cutting divisions. WEC Laser provides a comprehensive one-stop-shop service to all of its clients and we can cater for any manufacturing needs, from small one off brackets to ongoing £multi-million contract manufacturing projects.

Quality is at the heart of our operations and we pride ourselves on providing an unrivalled customer service which exceeds industry standards. We are committed to ongoing improvement and investment to stay ahead of the market, serving clients across a wide range of industries with our advanced metal laser cutting facilities.

Frequently Asked Questions

Angle and channel cutting is a fabrication process that involves cutting angles and channels from metal materials using specialised machinery such as saws or laser cutting equipment. This process is commonly used in construction, manufacturing, and engineering industries to create structural components with precise angles and dimensions. By accurately cutting angles and channels, it allows for the assembly of frameworks, supports, and other structures with ease.

Angle and channel cutting enable efficient production of components tailored to specific project requirements, contributing to the overall strength and stability of the finished product.

- Precision: It allows for precise cutting of angles and channels to exact specifications, ensuring components fit together seamlessly.

- Efficiency: The process is efficient, reducing material waste and minimising the need for additional machining or finishing.

- Versatility: Angle and channel cutting can be applied to various materials, including metals like steel, aluminum, and stainless steel, accommodating diverse project needs.

- Structural Integrity: By accurately cutting angles and channels, it enhances the structural integrity of fabricated components, ensuring they withstand loads and stresses effectively.

- Cost-Effectiveness: It streamlines production processes, reducing labor costs and production time, ultimately contributing to cost savings.

- Customisation: The flexibility of angle and channel cutting allows for the creation of customised components tailored to specific project requirements and designs.

Overall, angle and channel cutting play a crucial role in achieving precision, efficiency, and quality in manufacturing and construction applications.

21

Flat Bed Lasers

24

Press Brakes

4

Tube Lasers

24h

Cutting Capacity

Our Additional Services

Laser Box Section Cutting

Contract Manufacturing Services

Waterjet Cutting

Sheet Metalwork and Fabrication

Metal Bending and Folding

Angle, Channel & Open Profile Cutting

Laser Tube Cutting

What our Customers have to say about WEC Laser...

"Met with Stephen today who showed me around the facilities and helped me with an ongoing project. The machinery and level of organisation is honestly breathtaking, having seen much of the work in progress I am very much looking forward to working with WEC."

Frank Spear

"Just called to enquire about a replacement part for a post. Don't know much about them but John quickly pointed out what I needed and said he'd get one sent out in the post. Too easy. Thanks."

Lewis Foster

"Reliability and competitive prices plus helpful staff is why we work with WEC Laser"

“Delivery standards are always excellent. They are always on time."

Check out our latest video

WEC Laser is one of the UK's leading laser cutting company offering flat-bed, tube and box section laser cutting services throughout the UK. With 25+ lasers we are one of Europe's largest laser cutting operations