Laser cutting is a manufacturing process which can eliminate the need for machining on many engineering jobs, enabling you to save money on manufacturing costs.

Advantages of Laser Cutting

Laser cutting presents certain advantages over plasma cutting as this process is more precise and uses less energy when cutting steel and aluminium sheets. In addition, our latest Fibre laser machines, such as our 24Kw machine, are now approaching plasma machines in their ability to cut through thick materials.

The precision levels and edge quality achieved with laser cutting machines are better than traditional cutting methods, as the laser beam will not wear during the laser cutting process. Laser cutting technology also enables us to cut complex shapes without the need for tooling and at a similar or faster speed than other cutting methods. The fact that laser cutting technology offers reduced contamination of the work-piece presents certain advantages over traditional mechanical cutting techniques.

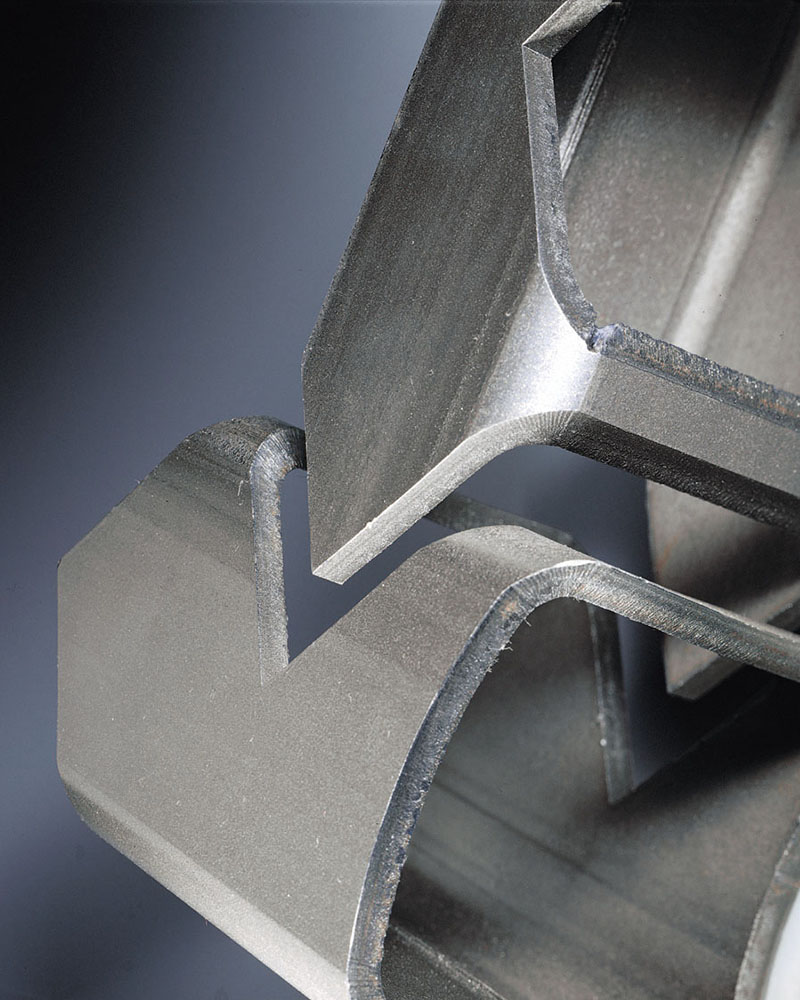

Laser cutting also allows us to cut small diameter holes with complex detail and good edge quality in either sheet, plate, tube or box section.