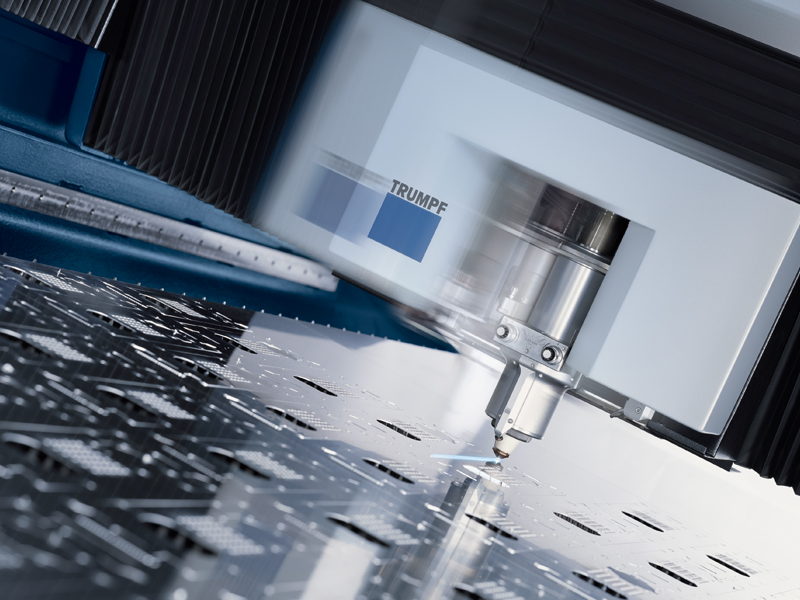

Over the past few years, WEC Laser has grown into the UK's largest laser cutting company, with over 20 flat bed lasers, 23 press brakes and 900 staff. Thanks to recent investments in the very latest 24kw fibre laser cutting machines, we can offer unrivalled cutting quality and very short leadtimes. Get your quote today!

Laser Cutting

Our Laser Cutting Capabilities:

Plate and Sheet Laser Cutting

Up to 4m x 2m

Laser Cutting Aluminium

Laser Cutting Copper + Brass

Material Grades

WEC Laser stocks and cuts most standard material grades and thicknesses, including:

- Mild steel

- S275

- S355

- S355JR

- S355J2

- S355MC

- 304 stainless steel

- 316 stainless steel

- Pickled & oiled

- Zintec

- Raex

- Hastelloy

- Titanium

- Optisheen

- Polished stainless steel

- Brush finished stainless steel

- Aluminium 1050

- Aluminium 5083

- Aluminium 6082

- Cromweld

- Corten

- Hardox

- Strenx

- Galv/galvanised steel

- Copper

- Domex

- Brass

- Patterned stainless steel

Our Cutting Capacity:

| Machines | Capacity | Thickness |

|---|---|---|

| 21 x flat bed lasers up to 24kw with full production automation | Laser profiling up to 4m x 2m | Laser cutting up to 30mm in all Material grades |

| 3 x 90k PSI Dynamic Head waterjet machines | Waterjet cutting up to 7.3m x 2.4m or 4m x 3m | Waterjet cutting up to 300mm in all Material grades |

| 1 x Hi-Def Plasma machine with full bevel capability | Hi-Def Plasma cutting up to 10m x 2.5m | Plasma cutting up to 50mm in all Material grades |

Why Choose WEC Laser?

WEC Laser, part of WEC Group, has established itself as one of the UK's largest laser cutting companies, with a workforce of more than 900 dedicated professionals in laser cutting, tube cutting, fabrication, powder coating, CNC machining, plasma cutting, and waterjet cutting divisions. WEC Laser provides a comprehensive one-stop-shop service to all of its clients and we can cater for any manufacturing needs, from small one off brackets to ongoing £multi-million contract manufacturing projects.

Quality is at the heart of our operations and we are accredited to all the main standards including ISO 9001:2015, EN1090 (CE/UKCA Marking), EN 3834 (fusion welding), EN 15085 (Rolling Stock Welding), ISO 40001, and ISO 14001 (Environmental). We offer full material traceability and can provide test certificates on request.

Frequently Asked Questions

WEC Laser can provide laser cutting for plates of up to 40mm in all standard material grades (mild steel, stainless steel, and aluminium). For parts over 30mm thick, we however recommend using our plasma cutting service (cutting capability of up to 50mm thick), or waterjet cutting (up to 300mm thick for any materials).

WEC Laser can provide laser cutting of thin gauge material from 0.5mm thickness onwards. We stock all standard material grades in mild steel, stainless steel, and aluminium from 0.9mm thick.

WEC Laser can also offer tube laser cutting up to 240mm diameter to all our customers. We can laser cut round tubes, box sections, RHS, angles, channels, and open profiles.

- Stainless Steel

- Mild Steel

- Aluminium

- Brass

- Copper

- Bronze

- Corten Steel

- Wear Plate

- High Strength Steel

- Tread Plate / Diamond Plate / Checker Plate

- Polished Stainless Steel / Optisheen Polished Stainless

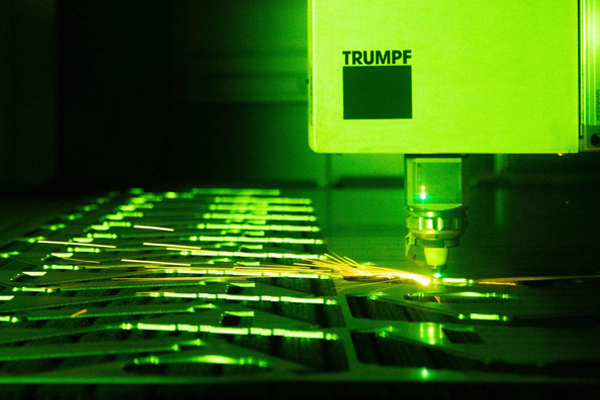

Laser cutting is a highly advanced technology that utilises a laser beam to cut a range of different materials.

When laser cutting is applied, a high-power laser is directed, via computer control, towards the material that is to be cut.

Depending on the material, this process can result in melting, burning, vaporising, or blowing it away using gas, resulting in an edge with an unparalleled surface finish.

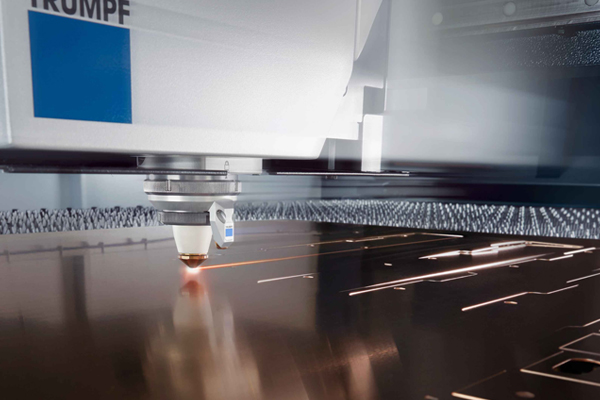

There are numerous advantages of laser cutting, including versatility, speed, and minimal material waste, making it ideal for intricate designs and rapid production processes.

It produces better edge quality and allows for the cutting of complex shapes without tooling.

Laser cutting also reduces contamination and enables the cutting of small diameter holes with intricate details.

21

Flat Bed Lasers

24

Press Brakes

3

Tube Lasers

24h

Cutting Capacity

Our Additional Services

Laser Box Section Cutting

Contract Manufacturing Services

Waterjet Cutting

Sheet Metalwork and Fabrication

Metal Bending and Folding

Angle, Channel & Open Profile Cutting

Laser Tube Cutting

What our Customers have to say about WEC Laser...

"Met with Stephen today who showed me around the facilities and helped me with an ongoing project. The machinery and level of organisation is honestly breathtaking, having seen much of the work in progress I am very much looking forward to working with WEC."

"Just called to enquire about a replacement part for a post. Don't know much about them but John quickly pointed out what I needed and said he'd get one sent out in the post. Too easy. Thanks."

"Reliability and competitive prices plus helpful staff is why we work with WEC Laser"

“Delivery standards are always excellent. They are always on time."

Check out our latest video

WEC Laser is one of the UK's leading laser cutting company offering flat-bed, tube and box section laser cutting services throughout the UK. With 21 lasers we are one of Europe's largest laser cutting operations